Oilstats

Prolonged use of a car engine in conditions where the oil cannot reach its correct working temperature will cause sludge formation and crankcase oil dilution, leading to excessive wear especially in the cylinder bores. Optimum engine power will only be delivered at correct temperatures. The elimination of drag in engines caused by cold oil is a most important consideration, especially with a racing engine, revving the engine without a load will not put much heat into the oil and devices for preheating the oil may not be available.

Prolonged use of a car engine in conditions where the oil cannot reach its correct working temperature will cause sludge formation and crankcase oil dilution, leading to excessive wear especially in the cylinder bores. Optimum engine power will only be delivered at correct temperatures. The elimination of drag in engines caused by cold oil is a most important consideration, especially with a racing engine, revving the engine without a load will not put much heat into the oil and devices for preheating the oil may not be available.

It is therefore desirable to control of the oil flow through the cooler by a thermostatic device, we call an oilstat, set to divert oil to the cooler at 80°C (although a wide range of settings is available for special applications). This is the minimum temperature required to evaporate and dispel contaminating substances.

Mocal Oilstats

Can be built into the oil cooler take off for most engines with spin-off filters, they add nothing to the thickness of the plate.

Are available as a separate unit to be fitted into the oil lines. Two sizes of oilstat for in line fitting are available.

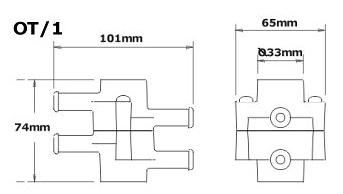

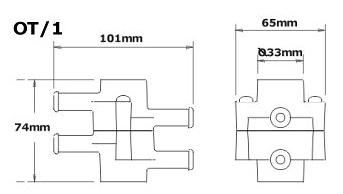

OT/1

Can be supplied with push on fittings for 3/8" or 1/2" bore hose only and is designed for smaller engines with relatively low oil flows.

Can be supplied with push on fittings for 3/8" or 1/2" bore hose only and is designed for smaller engines with relatively low oil flows.

Dimensions:

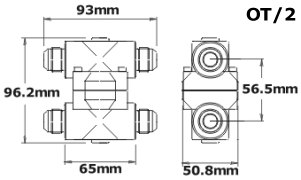

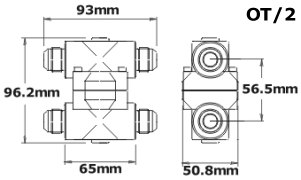

OT/2

Larger than OT/1, can be supplied with any form of push on or threaded connection, male or female.

Dimensions:

The bodies of the these units are die cast aluminium. Control is by a "waxstat", a mass produced item built to highest standards. They are light enough to be supported by the hoses, however a bracket is supplied with the slightly heavier OT/2, if further restraint is required. The oilstats should only be used where oil cooling is adequate, the sensing device will suffer permanent damage above 140°C, replacements are available.